Chemical Formula: MgF2

Refractive Index(at 550nm): 1.38

Transmission Wavelength (nm): 200~7,000

Melting Point(℃): 1260

Boiling Point (℃) : 2240

Density (g/cm3) :3.18

Evaporation Source: EB;Ta;Mo;Ta

Optical Coating is mainly employed on surface of optical components including lenses, prisms, windows, benches as well as various light wedges and beam split mirrors and so on.

Our main products are optical coating materials, precisely, the evaporation materials, such as SiO2, MgF2, Ti3O5, ZrO2, ZRT(ZrO2+TiO2) and so on, which are chiefly used on the anti-reflective coating laminated to the surface of above optics.

Our company has successfully developed and produced many optical materials that has reached high standards and ensure the hige pure raw materials due to market demand, by means of joint development by Japan and China, through all sorts of State institutes of scientific research and their subordinate factories. Quality of some products even surpass anything else of the kind made in Japan and Germany. So far all these products are exported to large precision optical enterprises located in Japan, Korea and America.

The Often-Used Coating Materials as Follows

Characterized as the Stable-and-Great Coating Evaporation Material in the World

A problem which is difficult to solve may occur in the production of optical coating. That is, the properties of the optical components are likely to be affected due to the occurrence of Splash. Components, on which tens of layers coated, and sometimes as much as two hundred layers are possibly used in the lenses specially used for cutting-edge cameras, IC exposure machines and filters for DWDM in communication. In that case, those expensive parts will become waste if holes occur in coatings.Therefore, we have solved this problem from the Aspect of the Material.

Based on the rational design of optical coatings and well-equipped evaporation equipment, both MgF2 and SiO2 products made in our company with few or no splashes thanks to the great quality of the material themselves, as they are especially suitable for the heavy current and multi-layer evaporation and their quality have surpassed the counterparts’ in Japan, America and Germany after being used and testified by many large international optical enterprises several years.

(1) MgF2

The optical evaporation material - MgF2 is a kind of essential material that is used in the production of optical components such as lenses etc. Owning the lowest refractive index and most consistent characteristic among the inorganic materials, it is widely used to enhance the transmittance of the optical lens and improve the properties and qualities of cameras or optical equipment.

In real production, through tungsten, molybdenum boat or electron gun, MgF2 can be heated and evaporated then coated to the optical lens surface in vacuum coating equipment. However, a most serious and difficult problem may occur in this simple process, that is, the splashes. The cutting-edge camera lens will be the useless because of them, which is one of the main causes for increasing production cost at present. There are many reasons why splashes come into being, and it is related to a series of factors such as granularity, purity, type of impurity and crystalline state owned by the MgF2.

Cooperated between Japanese and Chinese scientific researchers, we adopt advanced production techniques to succeed solving the splashes problem of the MgF2 optical evaporation material occurred in the coating process.

Strong Points & Highlights of our MgF2 are:

1.We adopt advanced crystal growth technology.

2.Strict & precise coating inspection in each production and batch are carried out to control a consistently stable high quality.

3.We supply competitive price & mass production.

Strict & precise coating inspection in each production batch are carried out to control a consistently stable high quality, which make our products enjoy a long-stable high quality.

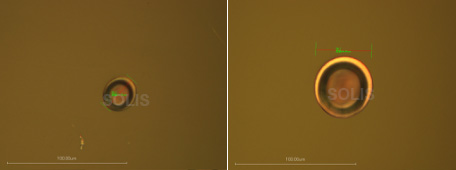

Defect contrast figure of thin film made by SOLIS and other company’s material MgF2 Granules:

Company 1: diameter 21.32um Company 2: diameter 20.88um

Company 3: diameter 31.76um Company 4: diameter 46.46um

MgF2

SOLIS

Ti3O5

ZrO2

Al2O3

HfO2