Quartz glass is a kind of high-purity special industrial technical glass composed of single component of silicon dioxide. It has superior physical, chemical, thermal, mechanical and optical properties. Its comprehensive performance is the most of glass materials, known as "Glass King".

The integrated circuit industry chain can be roughly divided into three main parts: circuit design, chip manufacturing, and package testing. The processing of semiconductor products mainly includes chip manufacturing (front-end, Front-End) and package (back-end, back-end) testing. Among them, the chip manufacturing process is complicated, the process is numerous, and the production process requires the use of a variety of auxiliary quartz devices. Therefore, the high-purity quartz material is a key auxiliary consumable widely used in the production process of the semiconductor IC chip.

Quartz wafer can be used as substrate in photolithography, such as Semiconductor Integrated Circuit, Optical Communication, MEMS, Photoelectric device and Led. Its main materials are: synthetic fused silica (JGS1), fused quartz (JGS2), Flame Fused Quartz (JGS3), and single crystal quartz crystal. According to different types, different performance and different prices, it can meet various purposes and requirements of customers, and provide customers with a wide range of choices with the best cost-effective products.

The difference between several quartz glass materials is:

1. Synthetic Fused Silica (JGS1), which has good transparency in the ultraviolet and visible light bands, contains no bubbles and impurities, and is used in the field of high-energy lasers to make optical components: lenses, prisms, and the like.

2. Fused Quartz (JGS2) is usually used for the mirror substrate. According to different levels, there are usually bubble dots and small bubbles.

3. JGS3 has a good transmittance in the infrared band, but domestic materials contain many bubbles, and there are no bubbles in the imported materials.

Single crystal quartz is grown from a special seed crystal. Different types of cuts result in different orientations of the seed crystals. One type of seed crystal is inside the wafer, called "With Seed", and another type of seed crystal is not inside the wafer, hence the name "seedless." Single crystal quartz can be divided into three regions: X/Y and Z regions. Seedless means that the wafer is in the pure X/Y or Z zone. Frequently used parameters are cut, common cut types: AT-cut, ST-cut, Z-cut, etc.

SOLIS BEIJING can manufacture the following size of quartz wafer:

Size(mm) | Thickness(mm) |

Φ25 | 0.1-1.5 |

Φ50 | 0.1-1.5 |

Φ50.8 | 0.1-1.5 |

Φ76.2 | 0.1-1.5 |

Φ100 | 0.15-1.5 |

Φ101.6 | 0.15-1.5 |

Φ125 | 0.15-1.5 |

Φ150 | 0.2-1.5 |

Φ152.4 | 0.2-1.5 |

Φ200 | 0.3-1.5 |

Φ203.2 | 0.3-1.5 |

50*50 | 0.1-1.5 |

80*80 | 0.1-1.5 |

85*85 | 0.1-1.5 |

100*100 | 0.15-1.5 |

106*106 | 0.15-1.5 |

150*150 | 0.5-1.5 |

Other Size | Can be customer-designed. |

Specification | Capability |

Tolerance | ±0.02-±0.25mm |

Roughness | Ra<1nm |

Surface Quality | S/D 10/5--80/50 |

TTV | ≤3um-≤10um |

BOW | 3um-5um |

Wrap | 3um-8um |

Parallelism | 5um |

Positioning Edge | 22.5mm-57.5mm |

Positioning Angle | 90°* Dep1mm |

Flatness | 1/10L-30L |

Impurity | No stripes、、cracks |

Material Purity | 4-7N;Based on different types |

Packing |

Lens Proofing Processing

Sapphire Window

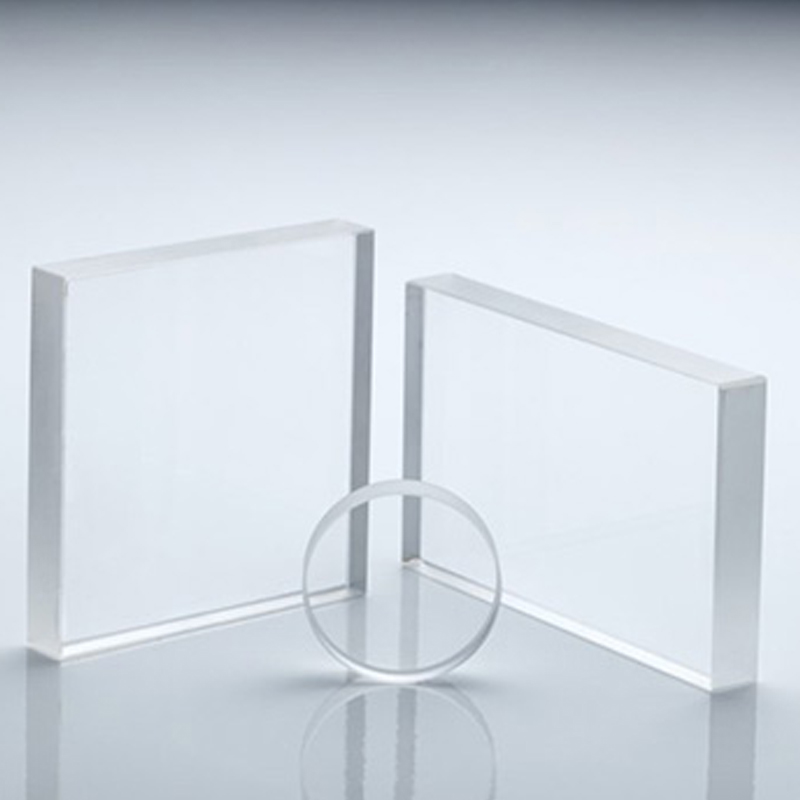

Optical Window

Optical Prototypes

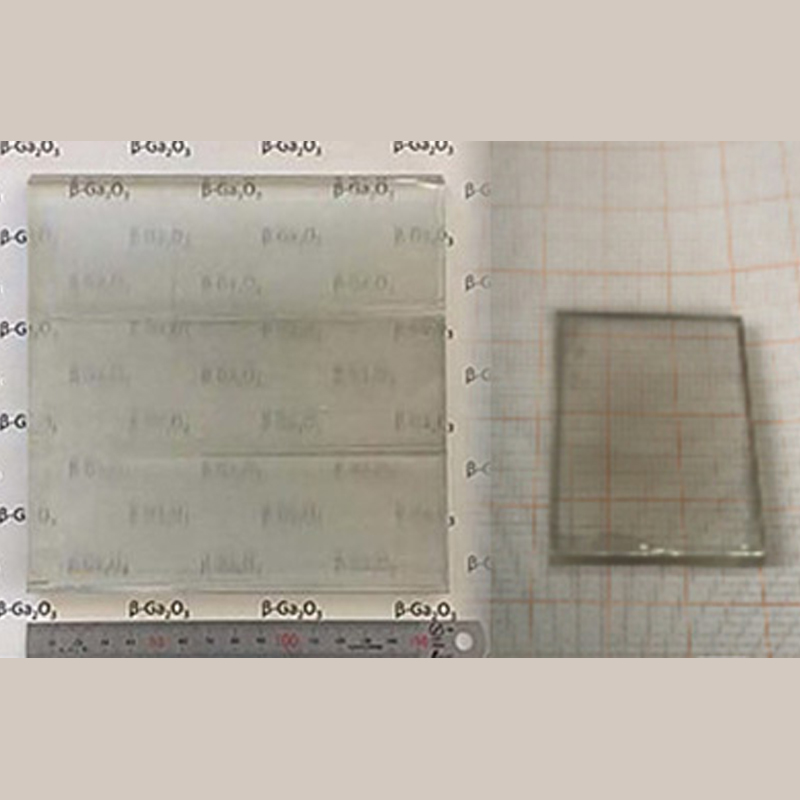

Gallium Oxide (β-Ga2O3) Crystal Window

Fused Silica Window