Lens proofing is also called secondary lens design. SOLIS Beijing Co., Ltd. undertakes all kinds of lens proofing or imitation processing. According to the needs of customers, it conducts a comprehensive test on the materials, dimensions, refractive index, focal length, face type, gluing and coating of lens samples, and makes new lens samples after accurate accounting, so as to achieve the ultimate goal of reducing high cost lens. The new lens can be exactly same or different with the original sample.

When conducting material testing, we provides two types of services:

The first type is proofing after destroying the original sample for accurate detection. This type of proofing can accurately know the material and various types of information. The sample is extremely accurate and the effect is excellent.

The second type does not damage the original sample for proofing after testing. The accuracy of this type of proofing is not as high as the damage proofing, but usually it can also obtain good sample results. But it may also cause some errors because the original material is not clear. In this case, we can help customers achieve the desired effect through the secondary optical design.

The accuracy will be higher if the application could be described exactly.

Number of proofing lens: 5-10 sets.

Lens materials can be: various types of optical glasses (Schott optical glass series, BK7, K9, K series, ZBAF series, ZF series, BaK series, SF series, ZK series, etc.), Fused Silica (including Corning 7980 series, Heraeus series) and quartz glass (JGS1, JGS2, JGS3), sapphire crystal and other infrared Crystals (zinc selenide, zinc sulfide, germanium, calcium fluoride and magnesium fluoride).

Besides lens duplication, our company can provide optical design template size list for optical design companies to reduce the cost of optical design.

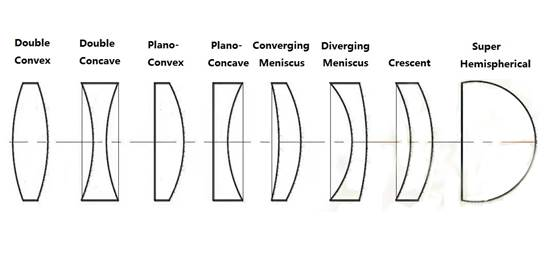

Common lens proofing and duplication types: plano-convex, plano-concave, biconvex, biconcave, meniscus, cemented lens.

The matching flat mirror can also be detected and make a sample. The process is basically the same.

Double Convex:

Is machined from two identical spheres. Since the two spherical faces are equal in radius, coma, distortion and chromatic aberration are effectively eliminated. They combine with other lenses to form an imagining system.

Plano Convex:

Are used in many applications, including the telescopes, sights, magnifiers, light receivers and condensers. A plano-convex lens consists of a plane and a sphere which combine with other lenses to form an imaging system.

Double Concave:

Is machined from two identical concave spherical surfaces. They form a negative focal length. Double concave lenses are often used in systems for beam expansion or increased focal length, and are also used in laser beam expanders, light readers, viewers and projection systems.

Plano Concave:

Is machined from a flat surface and a concave spherical surface. They form a negative focal length. Plano concave lenses are often used in systems to expand the beam or increase the length of the focal length.

Converging Meniscus, Diverging Meniscus and Crescent Lens:

If the lens is a convex-concave lens, then the convergence or divergence of the lens depends on the relative curvature of the two curved surfaces. If the two are equal (the crescent lens), the passing light beam neither converges nor diverge.

Cemented lenses, also called achromatic lenses, are made by cementing two single-piece lenses. The performance of multi-color (white light) imaging is much better than that of single lenses. Achromatic lenses are glued together by two lenses of different materials to correct the dispersion of the glass.

Lens Proofing Processing

Sapphire Window

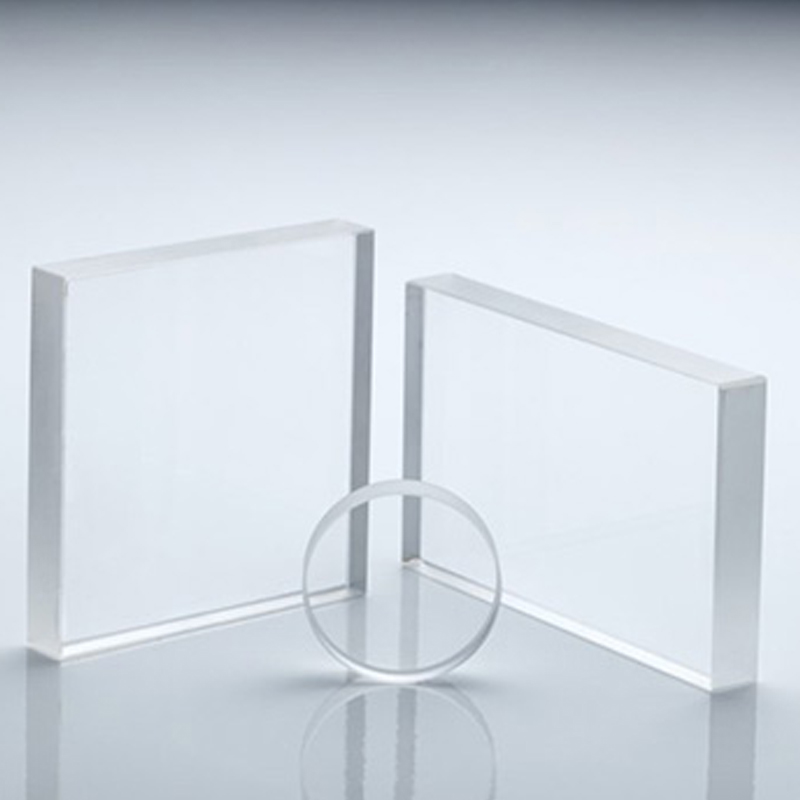

Optical Window

Optical Prototypes

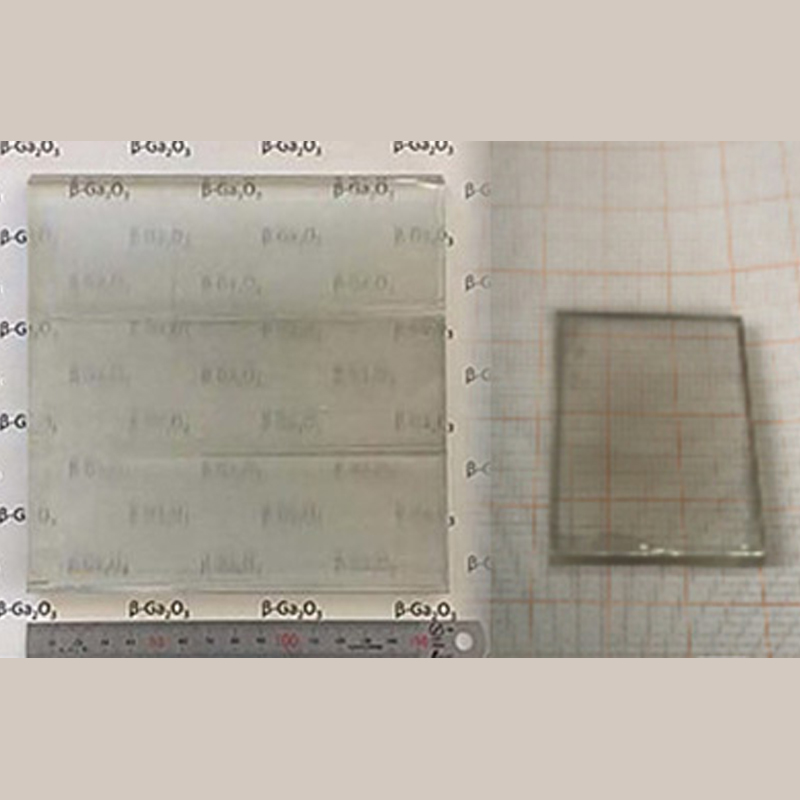

Gallium Oxide (β-Ga2O3) Crystal Window

Fused Silica Window